In any industry, hot work activities like welding, cutting, and grinding are an integral part of the manufacturing and maintenance process. However, these activities come with extensive dangers of fire and explosion risks, too. To mitigate these hazards and to ensure proper safety measures, NFPA (National Fire Protection Association) has established specific hot work requirements. If you are a safety manager, supervisor, or a Permit Authorizing Individual (PAI) in charge of hot work operations, it is important to understand and implement these regulations.

In this article, we’ll break down OSHA hot work permit requirements, explore related safety guidelines, and explain how Illustra Pro’s PAI Training equips you with the tools to create a safer work environment. Let’s begin!

What Is a Hot Work Permit?

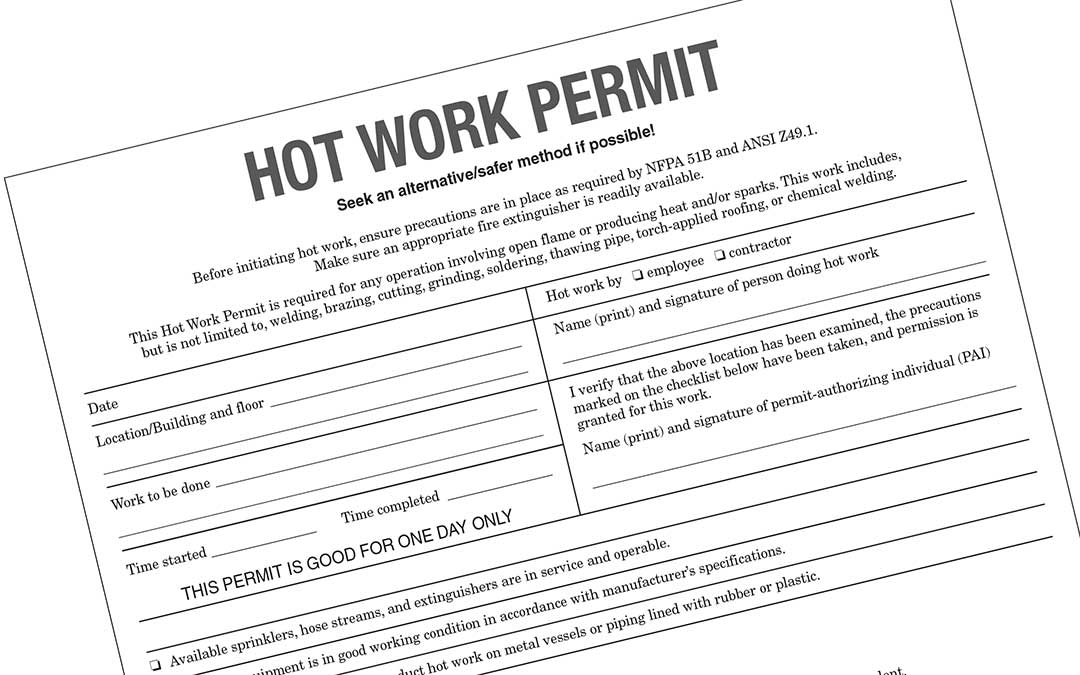

A hot work permit allows specific hot work operations in designated areas where there is a chance of fire hazards. This permit acts as a safety measure to identify, assess, and mitigate risks associated with hot work activities.

OSHA doesn’t provide a standard hot work permit form for employers to use, but they do have regulations regarding hot work. Hot work permits are mentioned in OSHA 29 CFR 1910.252 and 1926.352, particularly when these operations occur in areas with flammable or combustible materials. The permit is to make sure that there are sufficient fire prevention, protection, and hazard control measures in place before work on a project begins.

However, NFPA 51B Standard for Fire Prevention During Welding, Cutting, and Other Hot Work, requires a Hot Work Permit for any operation involving open flame or producing heat and/or sparks. You may download a permit from their website at https://www.nfpa.org/downloadable-resources/forms/hot-work-permit and use it to create your own customized permit specific to your company and responsibilities.

Importance of Hot Work Permits

Hot work operations generate heat, sparks, and open flames, which can ignite nearby materials. Without proper safeguards, these activities could lead to catastrophic fires, explosions, or injuries. A hot work permit system ensures accountability by documenting:

- Identification of hazards.

- Fire prevention and control measures.

- Assignment of responsibilities, such as fire watch requirements for hot work.

By implementing OSHA-compliant hot work permit systems, employers significantly reduce workplace risks.

Key OSHA Hot Work Permit Requirements

Understanding OSHA hot work permit requirements is critical for compliance and safety. Below are the essential components of a compliant hot work program:

• Assessment of the Hot Work Area

Before issuing a hot work permit, a comprehensive hot work area safety inspection must be conducted. This inspection ensures that flammable or combustible materials have been removed or adequately shielded. The assessment also includes proper ventilation of the work area to prevent any toxic fumes from accumulating. Another aspect of the assessment is the fire-resistant shields, blankets, or curtains, which contain sparks. The inspection also evaluates whether hot work can be relocated to a safer area, such as a designated hot work zone.

• Fire Watch Requirements for Hot Work

OSHA hot work permit requirements include a fire watch whenever hot work is conducted in areas where fire hazards cannot be completely eliminated. Fire watch personnel must be trained to recognize and respond to fire hazards. They should also remain in the area during the hot work. And most importantly, the personnel should have access to appropriate fire extinguishing equipment. The fire watch training at Illustra Pro ensures that fire watch personnel are equipped with the knowledge and skills to fulfill these responsibilities effectively.

• Implementation of Hot Work Safety Guidelines

Hot work safety guidelines are designed to keep the supervisors, workers, and workplaces safe during hot work activities. These safety guidelines come with some specific requirements, such as restricting hot work to authorized personnel and conducting atmospheric testing in confined spaces. Implementation of hot work safety guidelines reduces risks and helps in maintaining a safe working environment.

• Documentation and Maintaining Record

Hot work permits should be documented and retained for future reference. Proper documentation shows compliance during OSHA inspections and helps identify areas for improvement in safety protocols. Some of the key points of a hot work permit documentation include a description of the work to be performed, the location of the hot work, and approval signatures from the PAI.

OSHA Welding and Cutting Regulations

Welding and cutting are among the most common hot work activities. To address the specific hazards associated with these processes, OSHA has given a detailed overview of regulations in 29 CFR 1910.252. These include:

- Proper ventilation: Ensuring sufficient airflow to prevent exposure to hazardous fumes and glasses.

- Use of personal protective equipment (PPE): Requiring protective clothing, gloves, and helmets.

Supervisors overseeing welding and cutting activities must also ensure that operators are familiar with these regulations and that the work environment adheres to safety standards.

Hot Work Hazard Prevention: Best Practices

Effective hot work hazard prevention starts with robust training and strict adherence to safety protocols. Below are some best practices:

• Develop a Hot Work Safety Program

A comprehensive safety program should include:

- Clear guidelines for issuing hot work permits.

- Assign specific personnel responsibilities before, during and after hot work operations

- Training for PAIs, fire watches, and hot work operators.

- Emergency response plans.

Illustra’s training programs are designed to support organizations in building and implementing such safety programs, with a focus on ensuring OSHA compliance.

• Use Designated Hot Work Zones

Whenever possible, conduct hot work in a dedicated area designed to minimize fire risks. These zones should be free of flammable materials and equipped with fire suppression systems. For the maritime industry, there are additional OSHA and NAVSEA hot work permit requirements. Learn more about that in our next blog: Understanding Maritime Hot Work Permit Requirements.

• Train Permit Authorizing Individuals (PAIs)

PAIs are responsible for authorizing and overseeing hot work operations. Their role is crucial in ensuring compliance with OSHA hot work permit requirements. For example, Illustra Pro’s PAI Training provides in-depth knowledge of hazard identification, risk mitigation, and permit documentation to help PAIs perform their duties effectively.

• Conduct Regular Audits and Inspections

Routine audits and inspections help identify potential hazards and ensure adherence to hot work safety guidelines. This proactive approach develops a culture of safety and accountability.

Illustra Pro: Your Workplace Safety Partner

Managing hot work operations requires vigilance, expertise, and a commitment to safety. With OSHA hot work permit requirements, ensuring compliance is not just about avoiding penalties, it’s about protecting lives and property. By implementing these practices and investing in targeted training, you can ensure that your organization not only meets OSHA hot work permit requirements but also results in a culture of safety and accountability.

Illustra Pro is dedicated to helping organizations achieve workplace safety excellence. Our training programs focus on equipping supervisors, PAIs, and safety professionals with the knowledge and tools needed to manage hot work operations safely. Investing in specialized training, like Illustra’s Permit Authorizing Individual (PAI) Training, is a proactive step toward achieving these goals. Learn more about our programs by visiting Illustra’s PAI Training page.

Your team’s safety starts with the right training. Contact us today to create a safer work environment, compliant with OSHA requirements!